Questions? Get a Quick Response

Questions? Get a Quick Response

At AccuTec, the safety of people in industries where respiratory protection is needed is our top priority.

We take pride in offering advanced fit-testing systems like AccuFIT 9000 and AccuFIT 9000 PRO. In this article, you will learn how our AccuFIT instruments meet OSHA’s Fast Fit Protocol.

We adhere rigorously to the Occupational Safety and Health Administration (OSHA) standards. We conduct thorough testing to prove that our instruments meet all the requirements. In the following sections, we provide solid data and evidence supporting our claim. We will show how AccuFIT 9000 and AccuFIT 9000P PRO not only meet but also exceed OSHA’s Fast Fit Protocol standards.

The original fit-test protocol was developed at Los Alamos National Laboratory, H-5 Group in the 1970’s. Although the original protocol referenced the use of a generated aerosol of dioctyl phthalate, the important thing to remember is that the exercises of the fit-test protocol were (and are) independent of the actual challenge agent, which in modern systems is the ambient or generated aerosol of respiratory particulates. The protocol itself was rigorously tested against an orthogonal method which used sulfur hexafluoride as a challenge agent, and which proved to have an R2 value compared to the particulate-based protocol very close to unity. OSHA accepted the Los Alamos protocol which became regulatory with its publication as 29 CFR 1910.134.

Bear in mind that OSHA has approved these protocols with the sole purpose of establishing a test procedure which ensures that respiratory protection devices fit properly. These devices are vitally important to protect workers from inhaling dangerous airborne particles and vapors, but they are only effective if they fit. And, the only way to know that they fit is to perform a properly conducted fit test.

For about forty-five years the original protocol was the only one accepted by OSHA, but there were several entities (Health Canada, for example) who felt that the number of exercises (8) and their duration (1 minute each) were excessively conservative. In 2019 OSHA accepted a Fast Protocol which took only 2 ½ minutes to perform, and which has been shown to show an extremely close correlation to the results obtained by the original 1970’s protocol.

OSHA’s Fast Fit Protocol includes exercises which challenge the respirator’s ability to seal to the face of the wearer. In modern quantitative fit test protocols, the test generates a defensible metric which leaves no room for interpretation or guesswork on the part of the test administrator. OSHA is very interested in ensuring that the actual challenge to the respirator seal is sufficiently rigorous such that the test mimics the most extreme conditions found in the actual performance of the work-related tasks during which the respirator is worn. One very important way to accomplish this is to mandate that every test is performed in the same way, with the same exercises and same timing. This process is referred to as “the protocol”.

Using reliable fit testing systems, employing the appropriate protocol, and providing the appropriate (fit-tested) respirator, employers can reduce the risk of occupational exposure. They can also foster healthier work environments and enable a more safety-conscious culture for their employees.

This protocol offers many benefits to professionals in charge of respirator testing. Here’s how it can make their job easier and more efficient:

OSHA’s Fast Fit Protocol emphasizes efficiency by offering a shorter testing protocol. This allows for more people to be tested in less time. This reduces the burden of fit-testing coordination. Additionally, this also tends to ensure compliance with OSHA standards without compromising accuracy or tempting personnel to take shortcuts.

As an employer, one of your main concerns is the safety of your employees. OSHA’s Fast Fit Protocol ensures every worker uses a properly fitted respirator. This minimizes exposure to hazardous substances and reduces health risks.

Fit Testing systems that follow the protocol are designed to be user-friendly. This makes the testing process more accessible. The simplicity of the approved protocols allows for smoother fit-testing sessions – even for those who might not have extensive technical knowledge.

This protocol provides clear guidelines for fit test data interpretation. This means understanding the results is easier and faster. This generates informed decisions about employee respirator use. The focus of this protocol simplifies the evaluation process. It also ensures a straightforward analysis of fit test results.

Shorter fit testing protocols save time and resources. By using the OSHA-approved 2019 Fast protocols, you can optimize testing efficiency. This is without compromising on the quality of fit testing results. This cost-effective approach benefits both organization and the well-being of the employees.

OSHA’s Fast Fit Protocol sets specific procedures that employers must follow. This is to ensure a proper fit of respirators. These procedures apply to all OSHA-accepted fit test methods.

Key requirements of OSHA’s Fast Fit Protocol include:

Test subjects must choose the most suitable respirator from different models and sizes. This is to ensure a correct fit and comfort.

Test subjects will be shown how to wear a respirator correctly, as well as how to adjust strap tension, and check for an acceptable fit. Comfort assessment should also be conducted.

Test subjects must perform a user seal check to ensure a proper fit. If the seal check fails, a different respirator should be chosen and retested.

The fit test should be done while wearing all typical safety equipment.

Specific exercises are conducted to assess respirator/face seal performance.

For more information on OSHA’s fit testing requirements, check their official website.

AccuTec is committed to worker safety and regulation compliance. This is evident in the design and performance of our fit-testing instruments. Both AccuFIT 9000 and AccuFIT 9000 PRO are designed to meet OSHA’s Fast Fit Protocol. This is to ensure accurate and reliable fit testing for all tight-fitting respirators.

Both AccuFIT 9000 and AccuFIT 9000 PRO are engineered to withstand demanding environments. Their rugged construction ensures durability. They are also quick to deploy, allowing for efficient fit testing without delays.

We understand the importance of accurate fit testing in maintaining workplace safety. AccuFIT products are designed to get workers fitted quickly and accurately. This is to make sure that they have the right respiratory protection.

AccuFIT 9000 and AccuFIT 9000 PRO not only comply with OSHA’s Fast Fit Protocol. They also exceed expectations in providing reliable, efficient, and user-friendly fit-testing solutions.

Fit Factor describes the effectiveness of a respirator’s seal. Although the algorithm uses a harmonic mean, it is helpful to think of the Fit Factor as the ratio between the concentration of respirable particles in the ambient environment and the concentration of these particles in the test subject’s breathing zone. This metric assesses whether the respirator fits well enough to meet the minimum standards OSHA has determined are necessary to prevent the wearer’s exposure to airborne hazards and contaminants.

OSHA guidelines are specific when it comes to Fit Factor results. A Fit Factor of at least 100 is considered acceptable for half-facepiece respirators. Likewise, a Fit Factor of at least 500 is required for a full-facepiece respirator. These values ensure that the respirator provides enough protection to the wearer.

AccuTec’s commitment to follow the protocol led to a comprehensive experiment. This is to validate the performance of our fit-testing instruments, the AccuFIT 9000 and AccuFIT 9000 PRO. The goal was to ensure that our instruments produce the same results as those of our competitor.

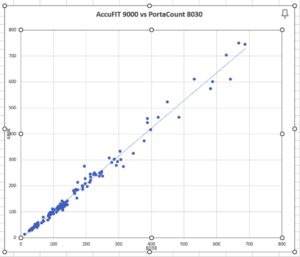

In this experiment, we built a specialized manifold with two inlet ports and two sample ports. One sample port was connected to an AccuFIT 9000. The other was connected to another respirator fit testing instrument, the PortaCount™ 8030. Both sample ports were able to sample exactly the same ambient and in-manifold aerosol concentration.

150 samples were collected with different ambient concentrations produced by different filter combinations on the sample inlets. The approach allowed us to simulate a wide range of in-mask concentrations, and also to assess the performance of both fit-testing instruments.

The resultant data points were plotted on a scatter plot with ‘8038 Overall Fit Factor’ (x-axis) and ‘AccuFIT 9000 Overall Fit Factor’ (y-axis). Calculating the results shows an R2 value of 98.68. This demonstrates a significant correlation between the Fit Factors determined by both devices.

This compelling evidence substantiates that the data collected following the 2019 OSHA Fast Fit Protocol results in near-identical Fit Factors for both AccuFIT 9000 and PortaCount™ 8030. Both fit testing instruments performed accurately in line with OSHA’s requirements. This means that both provide reliable results for proper respirator fit assessment.

AccuFIT systems offer comprehensive solutions that set them apart from the competition. Here are several compelling reasons why you should trust AccuFIT instruments:

They provide you with a versatile fit-testing solution that covers all tight-fitting respirators. This includes filtering facepiece respirators (N95, N99, N100), FFP1, FFP2, and FFP3 series respirators.

They incorporate OSHA’s streamlined 2019 CNC protocols. This means they make fit testing faster and more efficient while maintaining accuracy.

They feature an intuitive interface. This makes them accessible to users with varying technical knowledge.

They are equipped with six language options. This makes testing instructions and results easier to understand by users from diverse linguistic backgrounds. More language options will be available in October of 2023.

They are designed to withstand tough environments. This offers durability and consistent performance even in challenging work settings. The instruments are supplied with a hard-sided shock-resistant carrying/shipping case.

We offer a 3-year warranty on our products. We are confident in the durability and reliability of AccuFIT instruments.

When compared to the competition, AccuFIT systems offer a competitive price point. This is without compromising on quality.

AccuTec takes pride in providing excellent customer support. Our team is readily available to assist with any questions and concerns you may have, ensuring a smooth fit testing experience.

In conclusion, choosing AccuFIT 9000 and AccuFIT 9000 PRO for your respiratory protection plan is a decision that prioritizes worker safety and regulatory compliance. These OSHA-compliant fit testing solutions offer an all-in-one capability, ease of use, and real-time presentation, ensuring accurate and reliable fit testing results.

As you invest in AccuFIT Systems, you invest in the well-being of your workforce, fostering a healthier and safer workplace. Embrace the confidence and efficiency that AccuFIT systems bring to your fit testing procedures and let AccuTec be your trusted partner in achieving a higher standard of respirator protection for your organization.

Customer Service

info@accutec.com

(866) 393-2405 toll-free

Global Distribution & Service Center

201 S. Miami Ave

Cleves, OH 45002

Get the Latest News from AccuTec Right in Your Inbox.